Here is an article about cabinet hardware jigs, formatted as requested:

Make Cabinet Hardware Jig: Achieve Precision and Consistency

Installing cabinet hardware, such as knobs and pulls, can be a deceptively challenging task. While seemingly simple, inconsistencies in placement can significantly detract from the overall aesthetic of cabinetry. Uneven spacing, misaligned pulls, and crooked knobs are visually jarring and create a perception of unprofessional workmanship. A carefully constructed cabinet hardware jig provides a reliable method to ensure consistent and accurate placement, leading to a polished and professional finish.

The use of a jig, or template, eliminates the need for repetitive measuring and marking for each piece of hardware. Instead, the jig acts as a guide, providing precise locations for drilling pilot holes for screws. This not only saves time but also reduces the risk of errors, especially when installing hardware on a large number of cabinets or drawers.

Understanding the Need for a Cabinet Hardware Jig

The importance of a cabinet hardware jig becomes increasingly apparent when dealing with multiple installations. Manually measuring and marking each location, even with meticulous care, introduces opportunities for slight deviations. These small discrepancies, when multiplied across an entire kitchen or bathroom, become readily noticeable and detract from the overall appearance. A jig ensures that each piece of hardware is installed in exactly the same position, creating a uniform and professional look.

Beyond aesthetics, consistent hardware placement also contributes to functionality. Knobs and pulls that are installed at different heights or angles can feel awkward to use. Consistent placement ensures a comfortable and ergonomic experience for the user. The jig eliminates guesswork, allowing for a repeatable process that guarantees both visual appeal and ergonomic function.

Furthermore, a cabinet hardware jig protects the cabinet surfaces from damage. Repeated measuring and marking can leave visible scratches or marks, especially on delicate finishes. The jig allows for precise drilling without the need for extensive marking, minimizing the risk of cosmetic damage to the cabinetry. This is particularly important when working with high-end or custom-made cabinets.

Designing and Building a Custom Cabinet Hardware Jig

While commercially available cabinet hardware jigs offer a convenient solution, creating a custom jig tailored to specific hardware and cabinet styles provides optimal results. The process involves careful planning, precise measurements, and accurate execution. The materials used should be durable and dimensionally stable to ensure consistent performance over time.

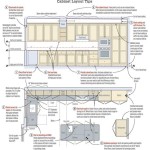

The initial step involves determining the desired placement of the hardware on the cabinet doors and drawers. Factors to consider include the overall style of the cabinetry, the size and shape of the hardware, and personal preferences. Common placements include centering the hardware on the cabinet face, aligning it with a specific design element, or positioning it at a predetermined distance from the edge.

Once the placement is determined, accurate measurements must be taken. This includes the distance from the edge of the cabinet to the center of the hardware, as well as the spacing between screw holes, if applicable. A precision ruler or digital caliper is essential for obtaining accurate measurements. These measurements will form the basis for the jig design and construction.

The jig itself can be constructed from a variety of materials, including wood, acrylic, or metal. Wood is a common choice due to its affordability and ease of workability. Acrylic offers excellent transparency, allowing for precise alignment with existing markings, while metal provides exceptional durability and resistance to wear. The choice of material depends on the desired level of precision, durability, and budget.

The jig design typically consists of a base plate with precisely drilled holes corresponding to the desired hardware placement. The base plate should be large enough to provide ample support and stability during drilling. For drawers, separate jigs may be needed to accommodate different drawer front heights or widths. The holes should be drilled with a drill press to ensure accuracy and perpendicularity. The size of the holes should be slightly larger than the diameter of the drill bit used to drill the pilot holes for the screws.

To further enhance accuracy, the jig can incorporate features such as adjustable stops or guide rails. These features ensure that the jig is consistently positioned on the cabinet face, preventing slippage or misalignment during drilling. Adjustable stops allow for quick and easy adjustment of the hardware placement, making the jig more versatile. Consider using clamps to secure the jig in position while drilling. Clamps prevent the jig from shifting during the drilling process. Use clamps with rubber tips to prevent damage to cabinetry.

Using a Cabinet Hardware Jig for Installation

Once the cabinet hardware jig is constructed, its proper use is essential for achieving consistent and accurate results. The process involves careful alignment, secure clamping, and precise drilling. Taking the time to follow these steps will ensure that the hardware is installed correctly the first time, saving time and frustration in the long run.

The first step is to position the jig on the cabinet face according to the desired hardware placement. This may involve aligning the jig with a specific edge, corner, or marking on the cabinet. Ensure that the jig is flush against the cabinet surface to prevent any gaps or misalignment. Any inconsistencies in the jig's position will translate into inaccuracies in the hardware placement.

Once the jig is properly positioned, it should be securely clamped to the cabinet face. This prevents the jig from shifting during drilling, ensuring that the pilot holes are drilled in the correct location. Use clamps that are specifically designed for woodworking, as these typically provide a secure grip without damaging the cabinet surface. Over-tightening the clamps can damage the cabinet finish, so be sure to apply just enough pressure to hold the jig firmly in place.

With the jig securely clamped, use a drill with a properly sized drill bit to drill the pilot holes for the screws. Apply consistent pressure and keep the drill bit perpendicular to the cabinet surface. Avoid forcing the drill bit, as this can cause splintering or damage to the cabinet. The depth of the pilot holes should be slightly shallower than the length of the screws to ensure a secure hold.

After drilling the pilot holes, remove the jig and install the hardware using the appropriate screws. Tighten the screws until the hardware is snug against the cabinet face, but avoid over-tightening, as this can strip the screw holes or damage the hardware. Use a screwdriver that is specifically designed for the type of screws being used. This will prevent slippage and ensure that the screws are properly tightened.

Inspect the hardware to ensure that it is properly aligned and securely attached. If any adjustments are necessary, loosen the screws slightly and reposition the hardware. Once the hardware is properly aligned, tighten the screws securely. Repeat this process for each piece of hardware, using the jig to ensure consistent placement.

By following these steps, a carefully constructed cabinet hardware jig enables the user to achieve consistent and accurate hardware placement, resulting in a professional-looking and functional cabinetry installation. The investment in time and effort to create a custom jig is well worth the benefits it provides in terms of accuracy, efficiency, and overall quality.

Maintenance of the jig involves keeping it clean of debris and ensuring that the drilled holes do not become enlarged over time. Occasional inspection and minor repairs will prolong the life and accuracy of the jig.

Simple Homemade Jig For Cabinet Door Pulls

Simple Homemade Jig For Cabinet Door Pulls

How To Use A Drilling Jig For Cabinet Handles And Knobs

Let S Make A Cabinet Hardware Jig Flipping The Flip

The Quickest And Most Consistent Way To Install Cabinet Hardware Out Of Woodwork

True Position Tools Cabinet Hardware Jig For Installation Of Handles And Knobs On Doors Drawer Fronts Tp 1934 The Home Depot

Kreg Adjustable Cabinet Hardware Jig For Accurate Hole Placement And Repeatable Results In The Woodworking Tool Accessories Department At Com

Let S Make A Cabinet Hardware Jig Flipping The Flip

Making A Jig To Install Cabinet Pulls

Kreg Cabinet Hardware Jig Khi Pull The Home Depot

Related Posts