How To Build A Kitchen Base Cabinet With Drawers and Doors

Constructing custom kitchen cabinetry offers a range of benefits, allowing for precise space optimization, personalized aesthetics, and cost savings compared to purchasing pre-made units. Building a base cabinet with both drawers and doors combines functionality and storage versatility, maximizing accessibility and utilization of available space. This article provides a comprehensive guide to building such a cabinet, outlining the necessary materials, tools, and step-by-step instructions.

The project requires careful planning and execution to ensure a structurally sound and visually appealing result. Accuracy in measurements and cuts is paramount, as even minor discrepancies can accumulate and impact the overall fit and function of the cabinet. The following instructions assume a basic understanding of woodworking techniques and familiarity with power tools. Protective eyewear and hearing protection are essential when operating power tools.

Key Point 1: Cabinet Design and Material Selection

The initial stage involves determining the desired dimensions and configuration of the base cabinet. Consider the available space within the kitchen, existing appliances, and intended storage needs. Standard base cabinet heights range from 34 ½ inches to 36 inches, including the countertop. Depth typically falls between 24 and 25 inches. Width is more variable, depending on the specific design. A common starting point is a cabinet width of 30 or 36 inches, allowing for adequate drawer and door space.

A detailed sketch or CAD drawing is crucial, outlining the cabinet's overall dimensions, the placement of drawers and doors, and the internal configuration of shelves or supports. Determine the number of drawers required, their respective heights, and the type of slides to be used. Similarly, decide on the size and style of the cabinet doors, including whether they will be full overlay, partial overlay, or inset. The design should also consider the thickness of the materials used, which will affect the final dimensions of the cut pieces.

Material selection significantly impacts the appearance, durability, and cost of the cabinet. Plywood is a popular choice for cabinet boxes due to its strength, dimensional stability, and resistance to warping. Hardwood plywood, such as birch or maple, provides a smooth surface suitable for painting or staining. Alternatively, melamine-coated particleboard offers a more economical option, but it is less durable and less resistant to moisture. Solid wood is typically used for face frames, drawer fronts, and door frames, offering superior strength and aesthetic appeal. Common hardwood choices include maple, oak, and poplar. The type of drawer slides will also influence the material choices, especially for the drawer boxes, which require sturdy construction to withstand the weight of the contents. Consider using dovetail joints or other robust joinery methods for drawer boxes.

For this particular build, the following materials will be required:

- ¾-inch plywood for cabinet sides, bottom, back, and shelves.

- ¾-inch solid wood for face frame stiles and rails.

- ½-inch plywood for drawer boxes.

- ¼-inch plywood for drawer bottoms.

- Solid wood for drawer fronts and door frames.

- Plywood or MDF for door panels (if using a recessed panel design).

- Drawer slides (full-extension, soft-close recommended).

- Cabinet door hinges (concealed hinges recommended).

- Screws, wood glue, nails.

- Sandpaper (various grits).

- Paint, stain, or clear coat finish.

Tools required include a table saw, miter saw, drill/driver, router (optional, for edge profiling), sander, measuring tape, square, clamps, and safety glasses. A brad nailer or pin nailer is helpful for assembling the face frame and securing drawer bottoms.

Key Point 2: Cabinet Box Construction

With the design finalized and materials procured, the next step involves cutting the plywood components for the cabinet box. Accurate cuts are crucial for ensuring a square and structurally sound cabinet frame. Use a table saw or circular saw with a guide to cut the cabinet sides, bottom, back, and internal shelves to the required dimensions. Prioritize accuracy; a slightly oversized piece can always be trimmed, but an undersized piece cannot be corrected.

The cabinet sides typically extend from the floor to the height of the countertop (minus the thickness of the countertop itself). The bottom panel provides structural support and serves as the base for the cabinet. The back panel adds rigidity and provides a mounting surface for attaching the cabinet to the wall. Internal shelves offer adjustable storage space. Consider using adjustable shelf pins for maximum flexibility.

After cutting the components, assemble the cabinet box using wood glue and screws. Apply glue to the edges of the panels and clamp them together to ensure a strong bond. Use screws to reinforce the joints. Ensure the cabinet is square by checking the diagonals. The diagonals should be equal; if they are not, adjust the cabinet until it is square before driving the screws home. A cabinet square is a useful tool for verifying squareness during assembly.

The back panel can be installed either flush with the back edges of the cabinet sides or recessed. A recessed back panel provides additional space for plumbing or electrical wiring. Secure the back panel with glue and screws or staples. A solid plywood back provides more structural stability than a thinner hardboard back.

Once the cabinet box is assembled, install any internal supports or dividers. These supports add strength and prevent the cabinet from sagging under heavy loads. Secure the supports with glue and screws or dowels. Ensure the supports are level and perpendicular to the cabinet sides.

Key Point 3: Face Frame, Drawers, and Door Installation

The face frame adds structural integrity and provides a finished appearance to the front of the cabinet. It is typically constructed from solid wood, such as maple or poplar, and consists of two vertical stiles and two horizontal rails. The stiles run the full height of the cabinet, while the rails are positioned at the top and bottom.

Cut the face frame components to the required dimensions using a miter saw or table saw. Join the stiles and rails using mortise and tenon joints, pocket screws, or dowels. Assemble the face frame using wood glue and clamps. Ensure the frame is square before allowing the glue to dry. A brad nailer can be used to reinforce the joints while the glue sets.

After the face frame is assembled, attach it to the cabinet box using glue and screws or nails. Align the face frame carefully with the front edges of the cabinet box. Clamp the frame in place and drive screws or nails through the frame into the cabinet sides and bottom. Ensure the screws or nails are countersunk to avoid protruding above the surface.

Drawer construction involves building drawer boxes and attaching drawer fronts. Cut the drawer box components (sides, front, back, and bottom) from ½-inch plywood and ¼-inch plywood, respectively. Join the drawer box components using dovetail joints, rabbet joints, or butt joints reinforced with screws. Dovetail joints offer superior strength and durability, while rabbet joints are easier to cut. Apply wood glue to the joints and clamp the drawer box together until the glue dries. Secure the drawer bottom with glue and staples or screws.

Install drawer slides in the cabinet box and on the drawer boxes, following the manufacturer's instructions. Accurate placement of the drawer slides is crucial for smooth drawer operation. Use a level to ensure the slides are perfectly aligned. Full-extension drawer slides allow the drawer to be pulled out completely, providing access to the entire contents. Soft-close drawer slides prevent the drawer from slamming shut.

Attach the drawer fronts to the drawer boxes using screws. Align the drawer fronts carefully with the face frame. Consider using adjustable drawer front mounting brackets for fine-tuning the drawer alignment.

Cabinet door construction typically involves building a frame and inserting a panel. The frame is constructed from solid wood, and the panel can be made from plywood, MDF, or glass. Cut the door frame components to the required dimensions using a miter saw or table saw. Join the frame components using mortise and tenon joints, cope and stick joints, or butt joints reinforced with screws. Cope and stick joints are commonly used for raised panel doors.

Assemble the door frame using wood glue and clamps. Insert the panel into the frame. If using a recessed panel, secure it with retainers or moldings. Ensure the door is square before allowing the glue to dry. A brad nailer can be used to reinforce the joints while the glue sets.

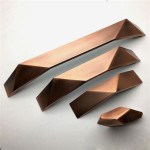

Install cabinet door hinges on the cabinet box and on the cabinet doors, following the manufacturer's instructions. Concealed hinges are a popular choice, as they are hidden from view when the door is closed. Adjust the hinges to ensure the doors hang straight and operate smoothly. Install door pulls or knobs to complete the door installation.

After completing the construction, sand all surfaces smooth and apply the desired finish. The finish protects the wood and enhances its appearance. Apply primer before painting or staining. Multiple coats of finish may be required for optimal durability and appearance. Allow the finish to dry completely before installing the cabinet in the kitchen.

30in Base Cabinet Carcass Frameless Rogue Engineer

How To Build Cabinets

How To Build Kitchen Base Cabinet Double Doors And Drawers Thediyplan

30 Kitchen Cabinet Add Ons You Can Diy Family Handyman

And Easy Shaker Cabinet Doors Drawers Diy How To

21 Base Cabinet Door Drawer Combo Momplex White Kitchen Ana

30in Base Cabinet Carcass Frameless Rogue Engineer

Diy Kitchen Base Cabinet 33 Wide With Double Doors And Drawer File Plans Only Cabinets Shaker

How To Build Under Cabinet Drawers Increase Kitchen Storage Diy Family Handyman

Diy Kitchen Cabinets Made From Only Plywood

Related Posts